ÖZGÜR KOÇAK

General Manager

Özgür Koçak, an Environmental Engineer with 27 years of experience, has been actively involved in a wide range of environmental technologies. Graduating from Istanbul Technical University in 1996, he has gained expertise in various disciplines of environmental engineering. His areas of expertise include market analysis, design calculations for wastewater treatment plants, tender file study, cost analysis, quotation preparation, process reports, software modeling, drafting drawings, commissioning, and project follow-up.

Özgür has worked for notable companies such as CULLIGAN TURKEY, where he specialized in designing potable water treatment plants of different capacities. He also had the opportunity to contribute to large-scale Potable Water Treatment Projects in Turkmenistan. After completing his military service, he joined GEZER ENDÜSTRİ, where he worked on multi-million-worth wastewater treatment and chemical recovery plants. Throughout his 22-year tenure at GEZER, he took on increasing responsibilities, eventually becoming the Chief of Tender Department and later the Tender Manager.

With a proven track record of successful project delivery, Özgür Koçak's expertise and dedication have made him a respected professional in the field of environmental engineering.

Özgür Koçak has recently taken on the role of General Manager at GLNACO RECOVER and RECYCLE COMPANY, starting from March 7, 2023, after leaving his previous position at GEZER ENDÜSTRİ. With a strong passion for innovation, Özgür is dedicated to building advanced water recycling plants, chemical recovery plants, and treatment systems for challenging wastewater streams. These streams include those from leachate, petroleum industries, dairies, detergent factories, food production facilities, and fertilizer companies.

In addition to his expertise in environmental engineering, Özgür is proficient in various software programs and well-versed in internationally recognized literature on wastewater treatment plant design. He is highly skilled in FIDIC Yellow Contracts, handling tender documents from esteemed organizations such as EBRD, World Bank, and Asian Development Bank. With advanced knowledge in Microsoft Office applications, AutoCAD 2D, ATV131, DWA Standards, WEF Standards, Metcalf & Eddy Standards, functional descriptions for PLC & SCADA systems, cross flow MBR/UF and cross flow RO systems, and ASTM dynamic modeling of wastewater treatment, Özgür brings a comprehensive skill set to his new role.

Özgür is fluent in English and is a native Turkish speaker. He also possesses intermediate-level proficiency in German, making him well-equipped for effective communication in international environments.

| Project Title | Construction of ROBERT BOSCH REXROTH EVOPORATION SYSTEM by means of VACUUM TYPE EVAPORATOR for the separation of cutting oil from water |

|---|---|

| Date | Jun 6, 2021 - Dec 20, 2021 |

| Period | 197 days |

| My responsibility in The Project |

All Design Works for technical and commercial quotation, commissioning service after installation

|

Some photos from the “Evoporation System for cutting oil – water separation” in ROBERT BOSCH REXROTH (BURSA – TURKIYE) |

|

| Project Title | Construction of Kastamonu WWTP (financed by IPA EU Investment, based on Fidic Yellow Book) |

|---|---|

| Date | Dec 3, 2019 - Jun 7, 2022 |

| Period | 917 days |

| Project Information |

Construction of Kastamonu Waste Water Treatment Plant for partially 31.978 m3/ day capacity (138.694 Population Equivalent) and partially for 38.267 m3/ day capacity (169.614 Population Equivalent), treating carbonous, nitrogen and phosphorus content of sewage,

|

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Some photos from the “Kastamonu WWTP” (KASTAMONU– TURKIYE) |

|

| Project Title | Construction of Iğdır WWTP (financed by IPA EU Investment, based on Fidic Yellow Book |

|---|---|

| Date | Apr 21, 2019 - Jul 1, 2022 |

| Period | 1167 days |

| Project Information |

Design Works for Iğdır Wastewater Treatment Plant with 25.184 m3/day capacity (125.000 Population Equivalent),

Construction of Iğdır Wastewater Treatment Plant with 21.038 m3/day capacity (105.000 Population Equivalent), treating carbonic, nitrogen and phosphorus content of sewage, |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from the “IĞDIR WWTP” (IĞDIR– TURKIYE) |

|

| Project Title | Construction of Merzifon WWTP (financed by IPA EU Investment, based on Fidic Yellow Book ) |

|---|---|

| Date | Feb 16, 2015 - Jun 8, 2017 |

| Period | 843 days |

| Project Information |

Design Works for “Merzifon Waste Water Treatment Plant,

Construction of Biological Waste Water Treatment Plant of 8.952 m3/day capacity (44.760 Population Equivalent), treating carboneous content of sewage |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Some photos from the “MERZİFON WWTP” (MERZİFON– TURKIYE) |

|

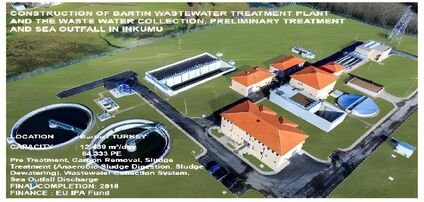

| Project Title | Construction of Bartın WWTP and The Waste Water Collection, Preliminary Treatment and Sea Outfall in İnkumu (financed by IPA EU Investment, based on Fidic Yellow Book) |

|---|---|

| Date | Sep 3, 2014 - Sep 29, 2016 |

| Period | 757 days |

| Project Information |

Design Works for “Bartın Waste Water Treatment Plant, Preliminary Treatment and Sea Outfall in Inkumu,

Construction of BARTIN Waste Water Treatment Plant of 12.439 m3/ day capacity (41.000 Population Equivalent), treating carboneous content of sewage |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from the “BARTIN WWTP” (BARTIN– TURKIYE) |

|

| Project Title | BORUSAN MANNESMANN – SEFAKÖY/ H2SO4 Acid Recovery Plant for Pickling Tanks |

|---|---|

| Date | Oct 13, 2017 - Apr 11, 2018 |

| Period | 180 days |

| Project Information |

Manufacturing of acid storage tank for 98 % concentration Sulfuric acid and transfer station,

Regeneration of sulfuric acid of 20 % concentration used in pickling tanks and production of FeSO4.7H2O with commercial value, Full automation for Acid regeneration Plant by means of PLC and operator panel systems, Transferring of concentrated sulfuric acid and regenerated acid back to pickling tanks through double – layer piping |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photos from BORUSAN MANNESMANN Project |

|

| Project Title | FEDERAL MOGUL Piston Segman ve Gömlek Üretim Tesisleri A.Ş-ADAPAZARI / Industrial Wastewater Treatment (3) |

|---|---|

| Date | May 23, 2017 - Dec 31, 2017 |

| Period | 222 days |

| Project Information |

Continuous Chemical Treatment System at 5 m³/h capacity for concentrated Acid / Alkali wash waste water, rinsing water and “oil separated waste water”,

Advance Treatment by Multi Layer Filter and Activated Carbon Filter for chemically treated waste water, Supply of Chemical Storage and Dosing Systems for Waste Water Treatment Plant, Full automation for Industrial Waste Water Treatment Plant by means of PLC and SCADA systems |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from FEDERAL MOGUL PISTON FACTORY WWTP |

|

| Project Title | Construction of Leachate Treatment Plant for Landfill Area of BALAKHANI / AZERBAIJAN |

|---|---|

| Date | Oct 28, 2015 - May 28, 2016 |

| Period | 213 days |

| Project Information |

Construction of 80 m3 /day capacity Leachate Treatment Plant

All mechanical equipments supply and erection in Container housing, start-up, training, supervision for operation of plant at site for 1 month and remote supervision for operation of plant for 2 months |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photos from LEACHATE TREATMENT PLANT |

|

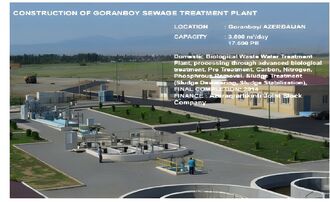

| Project Title | Goranboy DOMESTIC Wastewater Treatment Plant Construction – 3.500 m3 / day capacity / Azarbaijan |

|---|---|

| Date | Jan 16, 2013 - Jan 1, 2015 |

| Period | 715 days |

| Project Information |

Domestic Biological Waste Water Treatment Plant, processing through advanced biological treatment method, at 3.500 m³/day capacity - (17.500 Population Equivalent)

All mechanical equipment’s and laboratory equipment’s supply, erection, start-up, training and operation for 1 year , |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from GORANBOY (AZERBAIJAN) DOMESTIC WWTP |

|

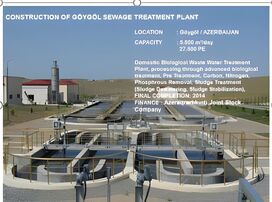

| Project Title | Goygol DOMESTIC Wastewater Treatment Plant Construction – 3.500 m3 / day capacity / Azarbaijan |

|---|---|

| Date | Jan 16, 2013 - Jan 1, 2015 |

| Period | 715 days |

| Project Information |

Domestic Biological Waste Water Treatment Plant, processing through advanced biological treatment method, at 5.500 m³/day capacity - (27.500 Population Equivalent)

All mechanical equipment’s and laboratory equipment’s supply, erection, start-up, training and operation for 1 year All electrical equipment’s and instrumentation supply, |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from GÖYGÖL (AZERBAIJAN) DOMESTIC WWTP |

|

| Project Title | Manisa – Kula Ultrafiltration and Reverse Osmosis Potable Water Treatment Plant Design and Construction – 5.700 m3 / day capacity / Manisa Kula – Turkey |

|---|---|

| Date | May 13, 2011 - May 13, 2012 |

| Period | 366 days |

| Project Information |

Hardness Removing Potable Water Treatment Plant of 5.700 m3/ day capacity, through Ultrafiltration and Reverse Osmosis System

Design and Project Execution, Supply of all the mechanical equipments and laboratory equipments, installation, commissioning, training and Operation of the Plant for 1 year |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from MANİSA KULA POTABLE WATER TREATMENT PLANT |

|

| Project Title | FORD OTOMOTİV SANAYİ A.Ş. Kocaeli Kocaeli / Yeniköy Industrial Waste Water Treatment Plant |

|---|---|

| Date | Oct 5, 2012 - Oct 7, 2013 |

| Period | 367 days |

| Project Information |

Manufacturing of Polyethylene Storage Tanks for Acid / Alkali rinse water sourcing out from Dyeing Plant,

Continuous Chemical Treatment System at 30 m³/h capacity for Acid / Alcali rinse water, Separation of oil from emulsified oily waste water by means of ceramic type ultrafiltration system, Continuous Chemical Treatment System and Biological Treatment System at 15 m³/h capacity for oily and paint waste water, Neutralization of chemical vapours by means of gas washing unit (gas scrubber), Supply of chemical storage and dosing systems, Full automation for treatment plant by means of PLC and SCADA systems |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, assistance for commissioning service, follow up committed OPEX values during operation of the plant

|

Photo from FORD OTOSAN INDUSTRIAL WATER TREATMENT PLANT |

|

| Project Title | GEBZE ORGANISED REGION CENTRAL DOMESTIC and INDUSTRIAL Wastewater Treatment Plant Construction and Operation (for 10 years) |

|---|---|

| Date | Sep 17, 2009 - Mar 15, 2011 |

| Period | 544 days |

| Project Information |

Construction of 6.400 m³/day capacity Industrial Waste Water Treatment Plant operating through Chemical and Advanced Biological Process, Pumping Station and Lifting Pipe Line” and Operation for 10 Years

Design and Project, Civil Construction, All mechanical equipments and Laboratory equipment Supply, Erection, Commissioning, Operation for 10 years and training |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, commissioning service, follow up committed OPEX values during operation of the plant for 10 years

|

Photos from GEBZE ORGANIZED INDUSTRIAL REGION WWTP |

|

| Project Title | Samra Thermal Power Plant Demineralization and Potable Water Treatment Plant Design and Construction / Samra - Jordan |

|---|---|

| Date | Apr 21, 2005 - Nov 15, 2005 |

| Period | 208 days |

| Project Information |

Pressurized MLF Unit 2 x 42 m3 / h

Pressurized GAC Units 2 x 42 m3 / h RO Unit 2 x 42 m3 / h Cation Exchanger Unit 2x 22 m3 /h Anion Exchanger Unit 2x 22 m3 /h Mixed bed Exchanger Unit 2x 22 m3 /h Chemical Storage and Dosing Unit QA / QC |

| My responsibility in The Project |

All Design Calculations and Drafting Works, calculation of OPEX during technical and commercial quotation stage, coordination with / assistance to Project execution team at site during construction works, commissioning service, follow up committed OPEX values during operation of the plant

|

Photos from SAMRA THERMAL POWER PLANT (CCCP) DEIONIZATION SYSTEM |

|

| Project Title | Rustimiyah / Baghdad – Iraq Waste Water Treatment Plant Renovation / Rustimiyah - Iraq |

|---|---|

| Date | Apr 7, 2004 - Apr 7, 2005 |

| Period | 365 days |

| Project Information |

Rehabilitation work of all electrical equipments at the site (motors, starters, indoor and outdoor lighting materials, power distribution and lighting panels etc.), supply of power and control cables and installation of these cables, testing of all damaged equipments and supply and installation of the new ones, if it is necessary (11kV switchgears and 1600 kVA transformers, electrical actuators, level measurement transmitters..)

|

| My responsibility in The Project |

All Design Calculations and Drafting Works, during technical and commercial quotation stage, coordination with

/ assistance to Project execution team at site during construction works, assistance for commissioning service. |

Photo from RUSTIMIYAH (IRAQ) WWTP |

|

| Project Title | Kerkh / Baghdad – Iraq Waste Water Treatment Plant Renovation / Kerkh - Iraq |

|---|---|

| Date | Apr 7, 2004 - Apr 7, 2005 |

| Period | 365 days |

| Project Information |

Rehabilitation work of all electrical equipments at the site (motors, starters, indoor and outdoor lighting materials, power distribution and lighting panels etc.), supply of power and control cables and installation of these cables, testing of all damaged equipments and supply and installation of the new ones, if it is necessary (11kV switchgears and 1600 kVA transformers, electrical actuators, level measurement transmitters..)

|

| My responsibility in The Project |

All Design Calculations and Drafting Works, during technical and commercial quotation stage, coordination with

/ assistance to Project execution team at site during construction works, assistance for commissioning service |

Photo from KERKH (IRAQ) WWTP |

|

| Project Title | Adana ENERJİSA (SIEMENS) CCPP Demineralization Plant Design and Construction / Adana - Turkey |

|---|---|

| Date | Apr 3, 2001 - Dec 31, 2002 |

| Period | 637 days |

| Project Information |

Pre – Treatment Unit

Reverse – Osmosis Mix. Bed Unit / Mix. Be 2x70 m3 / h Condensate Polishing System 2x75 m3 / h Chemical Storage and Dosage System |

| My responsibility in The Project |

Commissioning Works for the Deionisation system

|

Photo from ADANA ENERJISA (SIEMENS) DEIONISATION PLANT |

|

| Project Title | Mersin ENERJİSA (SIEMENS) CCPP Demineralization Plant Design and Construction / Mersin - Turkey |

|---|---|

| Date | Apr 3, 2001 - Dec 31, 2002 |

| Period | 637 days |

| Project Information |

Pre – Treatment Unit

Softening Unit 23 m3 / h Reverse Osmosis Unit 17 m3 / h EDI Unit 15 m3 / h |

| My responsibility in The Project |

Commissioning Works for the Deionisation system

|

Photo from MERSIN ENERJISA (SIEMENS) DEIONISATION PLANT |

|

| Project Title | ÇANAKKALE ENERJİSA (SIEMENS) CCPP Demineralization Plant Design and Construction / Mersin - Turkey |

|---|---|

| Date | Apr 3, 2001 - Dec 31, 2002 |

| Period | 637 days |

| Project Information |

Pre – Treatment Unit

Softening Unit 23 m3 / h Reverse Osmosis Unit 17 m3 / h EDI Unit 15 m3 / h |

| My responsibility in The Project |

Commissioning Works for the Deionisation system

|

| Project Title | FABAL ALÜMİNYUM SAN. ve TİC. A.Ş. Acid Recovery Plant |

|---|---|

| Date | Jul 10, 2014 - Dec 10, 2014 |

| Period | 153 days |

| Project Information |

GOEMAPUR AL 1400, acid retardation system removing aluminium from sulphuric acid

|

| My responsibility in The Project |

Design and drafting of the overall system, commissioning Works

|

Photo from FABAL ALUMINIUM FACTORY ACID RECOVERY PLANT |

|