Ammonia Stripping And Absorption By Acid To Generate Fertilizers

Industrial and municipal wastewater streams as well as effluents from biogas plants often contain high concentrations of ammonium nitrogen. Stripping with air or steam is a proven technology in terms of the treatment of ammonia-laden liquid streams. High solids loadings and corrosive contaminants demand for a high performance of a recycling plant.

Ammonia Stripping:

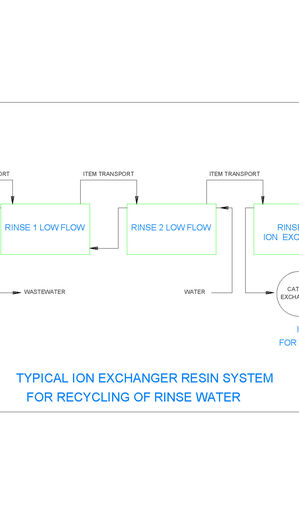

The actual separation process is achieved in a random packing column. The influent stream is introduced at the top of the packed bed and flows down through the column. Countercurrent to this, air or steam flows up and strips ammonia from the liquid phase. Ammonia-laden gases exit the top of the column and treated water is collected in the column sump. Key parameters that influence whether air or steam stripping should be used and how the entire process should be designed are as follows:

■ Local conditions

■ Wastewater stream temperature

■ Ammonia content ■ Energy source

■ Economic usability of end product features a higher efficiency

Air stripping in general causes lower operating costs and does not require any steam and cooling water sources.

Off Gas Treatment:

Various possibilities exist for the treatment of off-gases including recovery of ammonia water, absorption, and combustion. Stripping with steam allows for the off-gases to be concentrated in a subsequent distillation column. This process is energy-intensive but operates without residuals. The economically usable end product is ammonia water (ca. 20% NH3). The purity of this product allows for reuse as in, for example, Denox units. With air stripping, the ammonia containing off-gases can be discharged either by combustion or by absorption with an acid scrubbing process. In the scrubber stage, ammonia is absorbed by sulfuric acid. The end product is a concentrated salt solution which is mainly used as liquid fertilizer.