Sulfuric Acid Recovery Plants Through Chiller Methods

Pickling time decreases as temperature increases for sulfuric acid. Most pickling tanks are operated between 45 C and 60 C with a Sulfuric acid concentration of 15-20%. If that solution is cooled down to around 10-15 C, most of the ferrous sulfate will come out of the solution as ferrous sulfate heptahydrate crystals.

The solubility of ferrous sulfate in sulfuric acid can be seen in the Figure below. Iron concentration will be around 55-65 g/L Fe in pickling tanks. The process can be described as follows;

1. After filtering the acid solution, it is cooled down through the economizer before the crystallization. It is cooled with the solution that is coming out from the crystallization system.

While the temperature of the recovered acid is increased through the economizer, the temperature of the feed solution which enters to the crystallization system is decreased. Thus, the required energy for heating and cooling is minimized.

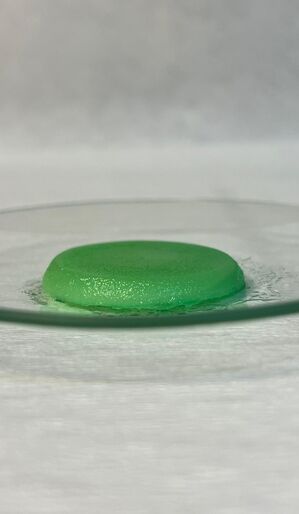

2. Cooled acid solution is fed to the crystallization system. Further cooling in the crystallizer will give Ferrous Sulfate Heptahydrate crystals (FeSO4.7H2O) because of the supersaturation created. Heat exchangers should be carefully designed in order to prevent crust formation.

3. Since the acid recovery process is a closed-loop continuous system, optimum and constant acid/iron concentrations can be maintained in the pickling tanks.

4. The by-product ferrous sulfate heptahydrate (FeSO4.7H2O) which has a commercial value can be used in the agricultural sector or wastewater treatment plants.

TYPICAL SKETCH FOR SULFURIC ACID RECOVERY PLANT THROUGH CRYSTALLIZER